|

| |

| Successor | LIMB |

|---|---|

| Founded | 1853 |

| Founder(s) | 2002 |

| Headquarters | Rijeka, Croatia (Yugoslavia) |

| Products | agriculture machinery tractor, engines, trucks, weapons |

Torpedo-Rijeka was a weapon, truck, tractor and engine manufacturer based in Rijeka, Yugoslavia (now Croatia). It built tractors from 1975 until 2002, using licensed Deutz-Fahr designs and technology. The company was well known for their licensed-Deutz engines. Torpedo-Rijeka went bankrupt in 2002, and part of its assets were purchased by Slovenia's Koroski Holding, moved to Slovenia and became LIMB tractors.

History[]

Beginnings by 1914[]

The Torpedo factory was established in 1853 as a result of an investment by an entrepreneur from Rijeka as a joint stock company called Fonderia Metalli, as a metal casting factory and the first product was anchors, while the secondary activity was the repair of steamboats. The factory did not progress so well until management was taken over by the English engineer Robert Whitehead who began producing engines for the Austro-Hungarian Navy, and the factory was renamed Stabilimento Tecnico Fiumano. In the 1860s, retired naval officer Ivan Vukić approached the factory with his new invention - the "shore savior" anti-ship weapon which was a boat loaded with explosives and together with Robert Whitehead he tried to commercialize this idea. Robert Whitehead begins later with a new idea by rejecting the idea of an explosive boat, and gathering his strength to develop an explosive fish that resembled a tuna when moving underwater. Initially, the torpedo was called a ship-mine (German 'Minenschiff'), and this new weapon was successfully demonstrated to the Austro-Hungarian Navy Committee on December 20, 1866. Later in 1868 on the Gemse artillery, torpedo launch tubes have been successfully installed, making it the world's first torpedo boat. Robert Whitehead successfully built marine engines, so for the engine that was installed in the Erzherzog Ferdinand Max number exhibited at the World Technology Fair in Paris, he took home the first prize. From 1870, mass production of torpedoes began, and in 1875 Robert Whitehead, together with his son-in-law, bought Stabilimento Tecnico Fiumano and renamed it Torpedofabrik Whitehead & Comp.'. Already in 1878, representatives of 18 countries came to Rijeka in order to conclude a contract with the factory Torpedofabrik Whitehead & Comp., and in 1881 the factory exported finished torpedoes all over the world. In 1889 Torpedofabrik Whitehead & Comp. developed torpedoes with larger calibers (381 mm, 450 mm and 533 mm), the original caliber was 356 mm. The United States purchased a license to manufacture torpedoes in 1892, and Torpedofabrik Whitehead & Comp. establishes a branch in the American city of Weymouth.

Before his death in 1905, R. Whitehead transformed the company into a joint-stock company Whitehead & Co., Societa in Azioni, headed by Count Edgar Hoyos, son of George Hovos. The English family business Vickers Ltd. and Armstrong-Whitworth & Co. buy from the heirs of the Whitehead family a majority stake. With the purchase, the factory was renamed Torpedo Fabrik Whitehead und Co Aktiengeselschaf and remained in English hands until the beginning of the First World War.[1]

During World War I, the Torpedo Fabrik Whitehead und Co Aktiengeselschaf factory was taken over by the Austro-Hungarian Navy, and all production was turned to the production of working materials.

From 1918 to 1945[]

After World War I and the Treaty of Versailles, the western part of Rijeka, where the Torpedo factory was located, belonged to Italy under contract, and in 1924 the factory became part of the Italian military industry. The general manager was Giuseppe Orlando, the factory was first renamed the “Societa di Esercizio Stabilimenti Whitehead”, and in 1930 the “Silurificio Whitehead di Fiume” SA. , Argentina, Finland, USSR. Technically, the torpedoes were improved so that the 533 x 7.20 torpedo model has a range of 4000 meters with a speed of 50 knots, while with a speed of 39 knots, a range of 8000m. With further development and investment, an aircraft torpedo 450mm x 5.18m was developed, which could be fired at a speed of 300km-h.To secure itself with a second production hall, on March 7, 1934, at a board meeting, a decision was made to establish a new company, Motofides, in Livorno (Italy) where motorcycles would be produced. In 1935, the Italian company FIAT became a shareholder in “Silurificio Whitehead di Fiume” SA, and two years later, in 1937, the production of torpedoes began at the factory in Livorno. This factory still exists today under the name WAAS, which still produces electric torpedoes[2]. During the war in 1942 alone, 1,170 torpedoes were produced, and in 1943, the factory produced about 160 torpedoes per month.

Period from 1945 to 1991[]

Allied bombing near the end of World War II destroyed most of the factory, so that after the war its reconstruction began and with that it was given the new name Jadran. In a partially trained factory, consumer goods such as padlocks, lighters, and burners are produced. A military production line was also set up. Shortly after 1947, the factory was renamed the Aleksandar Ranković Company, after a Serbian politician who was the right hand of Josip Broz Tito at the time. Then the factory was renamed the Torpedo Engine Factory in 1953, and the production program was marine diesel engines from small to large, as well as torpedoes.[3] The production of torpedoes was a secret, and until 1966, when the production of torpedoes stopped, 350 pieces of the Torpedo TZR type with a caliber of 533 mm, a range of 12 km and a speed of 40 knots were produced. In 1975, together with the German company Deutz-Fahr, the production of water-cooled diesel engines was adopted, through which the products are exported to many countries around the world. Since 1985, Torpedo has been investing in the development of its tractors, also based on Deutz. Since 1990, Torpedo has been experiencing financial problems. The first bankruptcy proceedings were initiated on 23 March 1990 in the Commercial Court in Rijeka, due to the inability to pay obligations to creditors.

The period from 1991 to End[]

With the expropriation of Torpedo by the Croatian state in 1991, the decline of that Rijeka factory began. The state reoriented production for the needs of the war, so in record time the engineers and workers of the Torpedo factory developed the Light Armored Vehicle, which entered production and use in 1993, and development began in 1992. This armored vehicle was based on the Torpedo HV 4x4 TK-130 T-7 truck which was previously developed in record time for the stated needs. The conversion of the Torpedo factory for the production of war equipment and unprofessional and unscrupulous management in 1993 introduced the company into financial problems, so the Rijeka District Court issued a compulsory settlement obliging the company to pay 22 million German marks to creditors within three years. Although this procedure gave the company a break, due to poor politically sound management, technological backwardness, lack of capacity, lack of vision and financial problems, and the growing dominance of imported products in the unprotected market, the company is sinking more and more. The state wanted to help by offering a loan in 1997 for the purchase of agricultural machinery and attachments from Torpedo[4], although the company account has been blocked since 1998. Bankruptcy proceedings were initiated only on 29 June 2000[5], and have not yet been fully completed. The original building of the factory in which the company Torpedo operated, due to its favorable location in the city, has been converted into a multi-purpose exhibition / concert space owned by the City of Rijeka.

Models[]

Tractors[]

| Model | Year(s) Produced | Horsepower | Engine Type | Misc Notes | Photo |

|---|---|---|---|---|---|

| Torpedo D 25 06 | 32 hp (24 kW) | licensed Deutz | |||

| Torpedo D 30 06 | 58 hp (43 kW) | licensed Deutz | |||

| Torpedo D 40 06 | 40 hp (30 kW) | licensed Deutz |

| ||

| Torpedo D 45 06 | 45 hp (34 kW) | licensed Deutz |

| ||

| Torpedo D 75 06 | 75 hp (56 kW) | licensed Deutz | |||

| Torpedo DX 55 A | 55 hp (41 kW) | licensed Deutz | |||

| Torpedo DX 75 A | 75 hp (56 kW) | licensed Deutz | |||

| Torpedo GTR 75 backhoe |

| ||||

| Torpedo Kvarner 45 | 45 hp (34 kW) | Torpedo | |||

| Torpedo Kvarner 55 | 55 hp (41 kW) | Torpedo | |||

| Torpedo Kvarner 55A | Torpedo | ||||

| Torpedo Kvarner 75 | 75 hp (56 kW) | Torpedo | |||

| Torpedo Kvarner 75A | Torpedo |

| |||

| Torpedo Kvarner 90A | Torpedo | ||||

| Torpedo RX 100 | 102 hp (76 kW) | Torpedo | licensed Deutz |

| |

| Torpedo RX 100 Euro | 102 hp (76 kW) | licensed Deutz | |||

| Torpedo RX 120 | 120 hp (89 kW) | Torpedo | licensed Deutz |

| |

| Torpedo RX 120 Euro | 120 hp (89 kW) | licensed Deutz | |||

| Torpedo RX 170 | 170 hp (130 kW) | licensed Deutz |

| ||

| Torpedo RX 170 Euro | 170 hp (130 kW) | licensed Deutz |

| ||

| Torpedo TB 1841 backhoe | licensed Deutz | ||||

| Torpedo TB 1941 backhoe | licensed Deutz |

| |||

| Torpedo TD 40 06 | 40 hp (30 kW) | licensed Deutz |

| ||

| Torpedo TD 40 06 A Adriatic | 40 hp (30 kW) | licensed Deutz |

| ||

| Torpedo TD 45 | 45 hp (34 kW) | licensed Deutz | |||

| Torpedo TD 45 Adriatic | 45 hp (34 kW) | licensed Deutz |

| ||

| Torpedo TD 45 06 | 45 hp (34 kW) | Torpedo | licensed Deutz | ||

| Torpedo TD 45 06 3 | 45 hp (34 kW) | licensed Deutz | |||

| Torpedo TD 45 06 A | 45 hp (34 kW) | licensed Deutz |

| ||

| Torpedo TD 45 06 C | 45 hp (34 kW) | licensed Deutz | |||

| Torpedo TD 45 06 J | 45 hp (34 kW) | licensed Deutz | |||

| Torpedo TD 45 06 K | 45 hp (34 kW) | licensed Deutz |

| ||

| Torpedo TD 45 06 S | 45 hp (34 kW) | licensed Deutz |

| ||

| Torpedo TD 48 | 48 hp (36 kW) | licensed Deutz |

| ||

| Torpedo TD 48 Adriatic | 48 hp (36 kW) | licensed Deutz |

| ||

| Torpedo TD 48 06 | 48 hp (36 kW) | Torpedo | licensed Deutz |

| |

| Torpedo TD 48 06 A | 48 hp (36 kW) | licensed Deutz |

| ||

| Torpedo TD 48 06 Adriatic | 48 hp (36 kW) | licensed Deutz | |||

| Torpedo TD 48 06 C | 48 hp (36 kW) | licensed Deutz |

| ||

| Torpedo TD 48 06 Special | 48 hp (36 kW) | licensed Deutz | |||

| Torpedo TD 55 A | 55 hp (41 kW) | licensed Deutz |

| ||

| Torpedo TD 55 A Adriatic | 55 hp (41 kW) | licensed Deutz |

| ||

| Torpedo TD 55 Adriatic | 55 hp (41 kW) | licensed Deutz | |||

| Torpedo TD 55 06 A | 55 hp (41 kW) | licensed Deutz |

| ||

| Torpedo TD 55 06 A Adriatic | 55 hp (41 kW) | licensed Deutz |

| ||

| Torpedo TD 60 06 | 60 hp (45 kW) | licensed Deutz |

| ||

| Torpedo TD 60 06 A | 60 hp (45 kW) | icensed Deutz |

| ||

| Torpedo TD 60 06 C | 60 hp (45 kW) | licensed Deutz | |||

| Torpedo TD 60 06 K | 60 hp (45 kW) | licensed Deutz |

| ||

| Torpedo TD 60 06 S | 60 hp (45 kW) | licensed Deutz |

| ||

| Torpedo TD 62 06 | 62 hp (46 kW) | licensed Deutz | |||

| Torpedo TD 62 06 C | 62 hp (46 kW) | licensed Deutz | |||

| Torpedo TD 65 06 | 65 hp (48 kW) | Torpedo | licensed Deutz | ||

| Torpedo TD 68 Mediterranie | 68 hp (51 kW) | licensed Deutz |

| ||

| Torpedo TD 68 06 | 68 hp (51 kW) | licensed Deutz | |||

| Torpedo TD 72 06 | 72 hp (54 kW) | licensed Deutz | |||

| Torpedo TD 72 06 A | 72 hp (54 kW) | licensed Deutz | |||

| Torpedo TD 72 06 H | 72 hp (54 kW) | licensed Deutz | |||

| Torpedo TD 75 Adriatic | 75 hp (56 kW) | licensed Deutz | |||

| Torpedo TD 75 A | 75 hp (56 kW) | licensed Deutz | |||

| Torpedo TD 75 A Adriatic | 75 hp (56 kW) | licensed Deutz | |||

| Torpedo TD 75 A S Compact | 75 hp (56 kW) | licensed Deutz | |||

| Torpedo TD 75 06 | 75 hp (56 kW) | Torpedo | licensed Deutz | ||

| Torpedo TD 75 06 A | 75 hp (56 kW) | Torpedo | licensed Deutz |

| |

| Torpedo TD 75 06 A Special | 75 hp (56 kW) | licensed Deutz |

| ||

| Torpedo TD 75 06 Adriatic | 75 hp (56 kW) | licensed Deutz |

| ||

| Torpedo TD 75 06 Special | 75 hp (56 kW) | Torpedo | licensed Deutz |

| |

| Torpedo TD 90 A Adriatic | 90 hp (67 kW) | licensed Deutz |

| ||

| Torpedo TD 90 06 | 90 hp (67 kW) | licensed Deutz | |||

| Torpedo TD 90 06 A | 90 hp (67 kW) | licensed Deutz | |||

| Torpedo TD 90 06 A Adriatic | 90 hp (67 kW) | licensed Deutz |

| ||

| Torpedo TD 90 06 A Special | 86 hp (64 kW) | Torpedo-Deutz | licensed Deutz |

| |

| Torpedo TD 90 06 S Special | licensed Deutz | ||||

| Torpedo TD 90 06 Special | 86 hp (64 kW) | Torpedo-Deutz | licensed Deutz | ||

| Torpedo TD 98 A | 98 hp (73 kW) | licensed Deutz | |||

| Torpedo TT-120 D | licensed Deutz |

| |||

| Torpedo TX 45 Euro | 45 hp (34 kW) | licensed Deutz |

| ||

| Torpedo TX 48 | 40 hp (30 kW) | licensed Deutz | |||

| Torpedo TX 48 Euro | licensed Deutz | ||||

| Torpedo TX 52 | 52 hp (39 kW) | licensed Deutz | |||

| Torpedo TX 55 | 55 hp (41 kW) | licensed Deutz |

| ||

| Torpedo TX 55 A | 52 hp (39 kW) | licensed Deutz |

| ||

| Torpedo TX 55 A Euro | 55 hp (41 kW) | licensed Deutz | |||

| Torpedo TX 65 | 61 hp (45 kW) | licensed Deutz |

| ||

| Torpedo TX 65 Euro | 61 hp (45 kW) | licensed Deutz |

| ||

| Torpedo TX 65 A | 61 hp (45 kW) | licensed Deutz | |||

| Torpedo TX 75 | 70 hp (52 kW) | licensed Deutz | |||

| Torpedo TX 75 Euro | 70 hp (52 kW) | licensed Deutz | |||

| Torpedo TX 75 | 70 hp (52 kW) | licensed Deutz | |||

| Torpedo TX 75 A | 70 hp (52 kW) | licensed Deutz | |||

| Torpedo TX 75 A Euro | 75 hp (56 kW) | licensed Deutz |

| ||

| Torpedo TX 80 Euro | 80 hp (60 kW) | licensed Deutz | |||

| Torpedo TX 80 A | 80 hp (60 kW) | licensed Deutz |

| ||

| Torpedo 9100 | licensed Steyr |

| |||

| Torpedo Deutz DX 110 | 110 hp (82 kW) | ||||

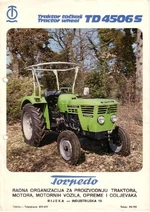

| Torpedo Deutz 4506 | 45 hp (34 kW) |

Tractors built by Torpedo for other companies[]

| Model | Year(s) Produced | Horsepower | Engine Type | Misc Notes | Photo |

|---|---|---|---|---|---|

| Bamford RX 100 | 100 hp (75 kW) |

| |||

| Bamford TD |

| ||||

| MeMo M100 | 102 hp (76 kW) | Deutz licensed engine | |||

| MeMo M120 | 117 hp (87 kW) | Deutz licensed engine |

| ||

| MeMo M170 | 170 hp (130 kW) | Deutz licensed engine | |||

| MeMo M451 | 45 hp (34 kW) | Deutz licensed engine |

| ||

| MeMo M452 | 45 hp (34 kW) | Deutz licensed engine | |||

| MeMo M453 | 45 hp (34 kW) | Deutz licensed engine | |||

| MeMo M481 | 48 hp (36 kW) | Deutz licensed engine | |||

| MeMo M482 | 48 hp (36 kW) | Deutz licensed engine | |||

| MeMo M483 | 48 hp (36 kW) | Deutz licensed engine | |||

| MeMo M511 | 51 hp (38 kW) | Deutz licensed engine | |||

| MeMo M513 | 51 hp (38 kW) | Deutz licensed engine | |||

| MeMo M681 | 68 hp (51 kW) | Deutz licensed engine |

| ||

| MeMo M751 | 73 hp (54 kW) | Deutz licensed engine | |||

| MeMo M751A | 73 hp (54 kW) | Deutz licensed engine |

| ||

| MeMo M752 | 73 hp (54 kW) | Deutz licensed engine | |||

| MeMo M752A | 73 hp (54 kW) | Deutz licensed engine | |||

| MeMo M753 | 73 hp (54 kW) | Deutz licensed engine | |||

| MeMo M753A | 73 hp (54 kW) | Deutz licensed engine |

| ||

| MeMo M754 | 75 hp (56 kW) | Deutz licensed engine | |||

| MeMo M803 | 80 hp (60 kW) | Deutz licensed engine | |||

| MeMo M803A | 80 hp (60 kW) | Deutz licensed engine | |||

| IMT Max 80 | 80 hp (60 kW) |

|

Trucks[]

Torpedo Kamioni SRT

Torpedo Kamioni SRT-L

- Torpedo HV TK-130 T-7 4x4

- Torpedo SRT-L

- Torpedo TK 130 T7 4x4

Armoured Vehicles[]

- LOV T1

- LOV T2

References[]

- ↑ http://www.gradri.hr/bastina/torpedo.html

- ↑ http://www.wass.it/WASSWEB/index.php?option=com_content&task=view&id=27&Itemid=342

- ↑ http://www.lokalpatrioti-rijeka.com/forum/viewtopic.php?f=28&t=197

- ↑ http://www.virovitica.net/suker-ce-zbog-traktora-blokirati-racun-zupanije/11305/

- ↑ http://www.poslovni-savjetnik.com/propisi/ustav-politicki-sustav-vlada-republike-hrvatske/odluka-o-izmjenama-uvjeta-kredita-odobrenih-

External Links[]

| |||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||