A Roots blower

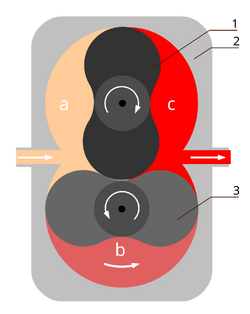

Diagram:

1 Rotary vane 1

2. Pump body

3. Rotary vane 2

a. Intake

b. Pumping

c. Forced air or air-fuel mixture into intake manifold

An Eaton M62 Roots-type supercharger is visible at the front of this Ecotec LSJ engine in a 2006 Saturn Ion Red Line

The Roots blower or Roots type supercharger is a positive displacement pump which operates by pumping air with a pair of meshing lobes not unlike a set of stretched gears. Air is trapped in pockets surrounding the lobes and carried from the intake side to the exhaust. The supercharger is driven directly from the engine's crankshaft via a belt or, in a two-stroke diesel engine, by spur gears.

It is named for the brothers Philander and Francis Marion Roots of Connersville, Indiana, who first patented the basic design in 1860 as an air pump for use in blast furnaces and other industrial applications. In 1900, Gottlieb Daimler included a Roots-style supercharger in a patented engine design, making the Roots-type supercharger the oldest of the various designs now available.

Applications[]

Of the three basic supercharger types, the Roots has historically been considered the least fuel efficient. However, recent engineering developments by Eaton Corporation have resulted in an improved Roots-type supercharger, known as the TVS, which is more efficient than their previous models. Unlike the basic illustration, most modern Roots-type superchargers incorporate three-lobe or four-lobe rotors. The latest design made by Kenne Bell, introduced for the Ford Mustang GT500 Super Snake, has four lobes per rotor, enhancing its efficiency through a reduction of pulsations.

The Roots-type supercharger is simple and widely used. It can also be more effective than alternative superchargers at developing positive intake manifold pressure (i.e., above atmospheric pressure) at low engine speeds, making it a popular choice for passenger automobile applications. Peak torque can be achieved by about 2000 rpm.

Accumulated heat is an important consideration in the operation of a compressor in an internal combustion engine. Per the wikipedia:ideal gas law, a compression operation will raise the temperature of the compressed output. Additionally, the operation of the compressor itself requires energy input, which is converted to heat and can be transferred to the gas through the compressor housing, heating it more. Although intercoolers are more commonly known for their use on turbochargers, superchargers may also benefit from the use of an intercooler. Internal combustion is based upon a thermodynamic cycle, and a cooler temperature of the intake charge results in a greater thermodynamic expansion and vice versa. A hot intake charge robs the engine of efficiency and produces diminishing returns from the compression process, while an intercooling stage adds complexity but can improve the efficiency by releasing some of the unneeded heat. Above about 5 psi (0.3 bar) the intercooling improvement can become dramatic.[citation (source) needed] With a Roots-type supercharger, one method successfully employed is the addition of a thin heat exchanger placed between the blower and the engine. Water is circulated through it to a second unit placed near the front of the vehicle where a fan and the ambient air-stream can dissipate the collected heat.

The Roots design was commonly used on two stroke diesel engines (popularized by the Detroit Diesel division of General Motors), which require some form of forced induction, as there is no separate intake stroke. The Rootes Co. two-stroke diesel engine, used in Commer and Karrier vehicles, had a Roots-type blower but the two company names are not connected.

The superchargers used on top fuel engines, funny cars, and other dragsters, as well as hot rods, are in fact derivatives of General Motors Coach Division blowers for their industrial diesel engines, which were adapted for automotive use in the early days of the sport of drag racing. The model name of these units delineates their size; i.e. the once commonly used "6-71" and "4-71" blowers were designed for General Motors diesels having six cylinders of 71 cubic inches each, and four cylinders of 71 cubic inches each, respectively. Current competition dragsters use aftermarket GMC variants similar in design to the -71 series, but with the rotor and case length increased for added pumping capacity, identified as the 8-71, 10-71, 14-71 etc.

Roots blowers are typically used in applications where a large volume of air must be moved across a relatively small pressure differential. This includes low vacuum applications, with the Roots blower acting alone, or use as part of a high vacuum system, in combination with other pumps.

Some civil defense sirens used Roots blowers to pump air to the rotor (chopper). The most well known are the Federal Signal Thunderbolt Series, and ACA (now American Signal Corporation) Hurricane. These sirens are known as "supercharged sirens".

Roots blowers are also used in reverse to measure the flow of gases or liquids, for example, in gas meters.

Technical considerations[]

Because rotary lobe pumps need to maintain a clearance between the lobes, a single stage Roots blower can pump gas across only a limited pressure differential. If the pump is used outside its specification, the compression of the gas generates so much heat that the lobes expand to the point that they jam, damaging the pump.

Roots pumps are capable of pumping large volumes but as they only achieve moderate compression, it is not uncommon to see multiple Roots blower stages, frequently with heat exchangers (intercoolers) in between to cool the gas. The lack of oil on the pumping surfaces allows the pumps to work in environments where contamination control is important. The high pumping rate for hydrocarbons also allows the Roots pump to provide an effective isolation between oiled pumps, such as rotary compression pumps, and the vacuum chamber.

A variant uses claw-shaped rotors for higher compression.

The Roots-type blower may achieve an efficiency of around 70% while achieving a maximum pressure ratio of two. Because a Roots type blower pumps air in discrete pulses (unlike a screw compressor), pulsation noise and turbulence may be transmitted downstream. If not properly managed (through outlet piping geometry) or accounted for (by structural reinforcement of downstream components), the resulting pulsations can cause fluid cavitation and/or damage to components downstream of the blower.

Comparative advantages[]

Rotary lobe blowers, commonly called boosters in high vacuum application, are not used as a stand alone pump. In high vacuum applications the boosters pumping speed can be used to reduce the end pressure and increase the pumping speed of other vacuum pump systems in the medium to low vacuum range.

Related terms[]

The term "blower" is commonly used to define a device placed on engines with a functional need for additional airflow using a direct mechanical link as its energy source. The term blower is used to describe different types of super chargers. A screw type super charger, Roots type super charger, and a centrifugal super charger are all types of blowers. Conversely, a turbocharger, using exhaust compression to spin its turbine, and not a direct mechanical link, is not generally regarded as a "blower" but simply a "turbo".

See also[]

- TVS Supercharger

- Turbocharger

- Glossary Index

References[]

- (April 5, 2002). Roots Type Superchargers Explained. SuperchargersOnline.com. Accessed March 31, 2008.

- Blower Briefing. Tom Henry Racing. Accessed March 31, 2008.

- Eaton TVS Supercharger The Eaton TVS Supercharger. Accessed 31 March 31 2008

External links[]

| |||||||||||||||||||||||||||||||||||

| This page uses some content from Wikipedia. The original article was at Rootes type supercharger. The list of authors can be seen in the page history. As with Tractor & Construction Plant Wiki, the text of Wikipedia is available under the Creative Commons by Attribution License and/or GNU Free Documentation License. Please check page history for when the original article was copied to Wikia |